contact

|

Functions |

Description |

√ |

|

Working mode selection |

Can select EFI (12V), GDI (65V) or PIEZO (140V) operating mode based on the injector type. |

√ |

|

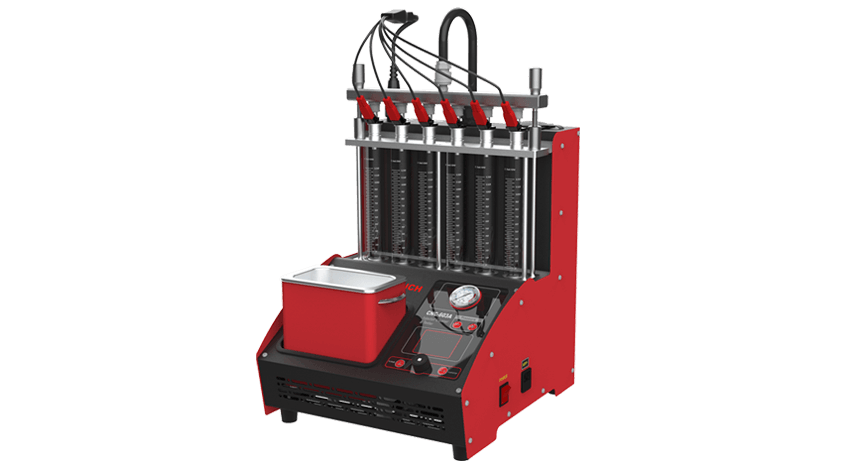

Ultrasonic Cleaning

|

Capable of simultaneously ultrasonic cleaning multiple injectors, effectively removing carbon buildup. |

√ |

|

Low resistance testing |

Supports low-resistance injector testing, capable of detecting short circuits and open circuits in fuel injectors. |

√ |

|

Uniformity/Spray Testing Function |

Detects the uniformity of fuel injection quantity for each injector and the spray atomization of the injector can be comprehensively and carefully observed using the background light. |

√ |

|

Sealing Test Function |

Tests the sealing and leakage of injectors under system pressure. |

√ |

|

Fuel Injection Quantity Detection Function |

Measures the fuel injection quantity of injectors under a constant 15-second injection condition. |

√ |

|

Automatic Cleaning and Testing Function |

Under specific working parameters, realistically simulates injector testing under various conditions. |

√ |

|

Reverse Flush Function |

For the uniformity/spray testing item, performs a reverse flush using a reverse flush adapter to remove internal injector contaminants and residues attached to the filter screen. |

√ |

|

Non-Dismantle Cleaning Function |

Equipped with various non-dismantle cleaning adapters, allowing non-dismantle cleaning and maintenance for multiple vehicle models. |

|

|

Host power supply |

AC110V/AC220V 50Hz/60Hz

|

Simulation speed range |

100~9900rpm Step length 10rpm

|

|

Host power |

500W |

Pulse Width

|

0.1-25ms, step length: 0.1ms |

|

Fuel tank capacity |

2500 ml |

Resistance test accuracy |

1% |

|

Ultrasonic cleaning machine power |

100W |

Resistance test range |

0-100Ω |

|

Working pressure |

0.1-9bar |

Host size |

412×398×550mm |

Do not place anything on the control panel to prevent from breaking the measuring cup because it is made from vulnerable. Do not disconnect hose before the system pressure reaches "0".

Always ensure that the provided power supply is well contacted with ground safely.

The unit is designed with warning function. When the level switch checks the liquid inside the tank less than the lowest line, the unit will utter the warning sound and meanwhile stop the fuel pump and injectors automatically, and then the unit returns to the stop state. The unit will stop warning until the liquid is supplied enough. At this time pressing the ENTER key will run the unit again.

Clean the control panel in time and Keep the pulse signal cable away from the liquid.