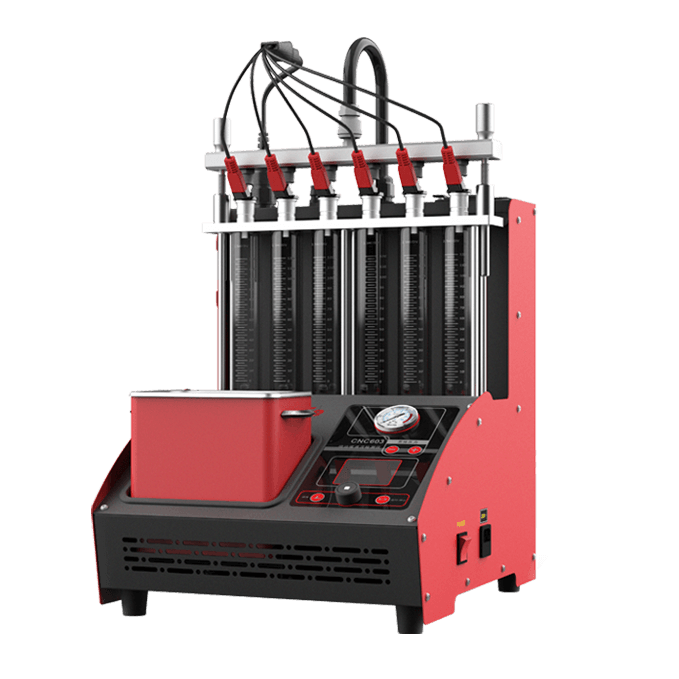

SmartSafe CNC603 cleaning injectors with ultrasonic, and can clean multiple fuel injectors at the same time. Combined with ultrasonic technology and microprocessor hydraulic control cleaning detection technology, CNC603 is an ideal tool for injector cleaning and testing.

contact

About the practical introduction of CNC-603A ultrasonic fuel injector cleaner, SmartSafe has prepared a wonderful video explanation for you. For more practical content, click on the video training center!

About the full-function introduction of CNC603 ultrasonic fuel injector cleaner, SmartSafe provides you with a comprehensive solution, and it will be a good helper in your shop!

|

Functions |

Description |

√ |

|

Ultrasonic Cleaning

|

Capable of simultaneously ultrasonic cleaning multiple injectors, effectively removing carbon buildup

|

√ |

|

Uniformity/Spray Testing

|

Detects the uniformity of fuel injection quantity for each injector and allows comprehensive

observation of the injector spray pattern using background lighting

|

√ |

|

Sealing Test

|

Tests the sealing and leakage of injectors under system pressure

|

√ |

|

Fuel Injection Quantity Detection

|

Measures the fuel injection quantity of injectors under a constant 15-second injection condition |

√ |

|

Automatic Cleaning and Testing

|

Under specific working parameters, realistically simulates injector testing under various conditions

|

√ |

|

Reverse Flush

|

For the uniformity/spray testing item, performs a reverse flush using a reverse flush adapter to remove

internal injector contaminants and residues attached to the filter screen

|

√ |

|

Non-Dismantle Cleaning

|

Equipped with various non-dismantle cleaning adapters, allowing non-dismantle cleaning

and maintenance for multiple vehicle models

|

√ |

|

Power Supply

|

AC110V/AC220V 50Hz/60Hz

|

Pulse Width

|

0.5~25ms Step length 0.1ms

|

|

Main Engine Power |

300W |

Timer Range |

1~10min |

|

Ultrasonic Cleaning Power |

50W |

Tank Capacity |

3L |

|

Revolutions Per Minute |

10~9990rpm Step length 10rpm |

Size |

396X380X446mm |

The transparent tubes are made of glass. So, do not place other items around the device to avoid scratching and fragmenting the tubes.

Disassembly of the tubes should be performed after the system pressure is displayed as zero.

It must be ensured that the power supply provided is grounded well.

Take good care of the machine. If the protective film on the control panel is stained with the cleaning agent, please wipe it off in time. Also, keep the pulse signal lines away from the cleaning agent and test the solution.